Different Paradigms for Lean Six Sigma Integration

• Six Sigma and Lean as Conflicting

• Six Sigma as a Sub-Set of Lean (Lean Bias)

• Lean as a Sub-Set of Six Sigma (Six Sigma Bias)

• Separate but Equals

• Integrated

Next Evolution ¨C Continuous Improvement

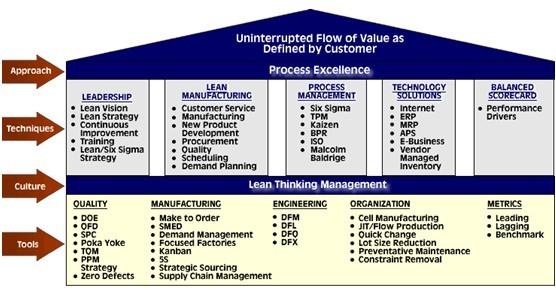

Business Process Leadership

Operation Excellence

Enterprise Process Leadership

Synergies of an Integrated Approach

• A value stream state approach for identifying opportunities coupled with a powerful data driven approach for prioritizing then addressing the opportunities

• The knowledge of how and when to apply the right methodology and tools to the right opportunity

• Link between Lean flow, velocity, speed and inventory and Six Sigma variation

• The lasting organizational benefits of a culturally driven, behavior based approach, augmented with the data driven discipline

• A value stream approach to run the entire business with a sophisticated problem solving methodology to apply when necessary

The Final Hurdle?

• How improvement is implemented

Seemingly Contradictory

Six Sigma ¨C utilizes trained, dedicated, belts to facilitate improvement across organization in a project environment on a process

Lean ¨C Leverages mentor/mentee relationships across the entire organization to facilitate improvement at the lowest possible level within the daily work routine in the value stream

History of Six Sigma Resources

Early in deployment

• Driven by dedicated Black Belts

• Function outside of their home departments

Continuing stages of deployment

• Growth in the population of Green Belts

• Green Belts function in home department

• Improvement is driven by a mix of Black Belts and Green Belts

Mature deployment

• Most of the improvement is driven by non-dedicated Green Belts

• Black Belts become an enabler to Green Belt projects

History of Lean Resources

• Long history of Gemba with improvement at the lowest possible level of the organization while moving toward the ideal state

• Cultural evolved and skill set developed over a long period of time

Final Hurdle or Evolution?

Lean view of implementation with Six Sigma skill set

Ideal State

• Improvement is everyone¡¯s job

• Engrained in culture

• Project when required

• Stable organization

Green Belt dominated

Future State

• Project environment

• Home area improvement

• Green Belt dominated

Black Belt dominated

Current State

• Project environment

• Outside home area

• Black Belt dominated

• Issue oriented

An Ideal State for Lean Six Sigma Implementation

• Lean thinking and behaviors are engrained across the organization

• Value stream management is deployed to achieve process oriented systems thinking

• Six Sigma Green Belt skill level is obtained by everyone within the organization

• The organization is stable enough to warrant improvement as an everyday activity within the daily work flow of all personnel

• A small number of Black Belts and Master Black Belts are reserved to chronic, mega-projects with all other improvement activity occurring in a non-project environment

• Culture change that occurs over a period of time where continuous improvement becomes everyone's job

• The structure is outlined within the organization¡¯s business operating system

Lean£«Six Sigma = Daily Work ¡ú Continuous Improvement ¡ú Everyone¡¯s Job

» More Information